Canning

The term canning refers to a process in which foods are heated in hermetically sealed containers for a specific time at a specific temperature in order to eliminate microbial pathogens that are not safe for public health and micro-organisms as well as for enzymes that deteriorate the food during storage.

Currently, a large number of fruits, vegetables, meats, sauces, and confectionery products are preserved by canning. The canning industry has great potential for growth as it is a process that does not use any chemicals in the preservation.

Watch Lecture Video Part Ist

Watch Lecture Video Part IInd

Watch Lecture Video Part IIIrd

History of Canning: The important historical developments in canning are as follows:

- The credit for the invention of canning goes to Nicolas Appert, a French confectioner who was awarded a prize by the French government in 1809 for developing a new method of heat preservation of food in sealed containers, and after whom the process of canning is named as appertization.

- In 1810, Appert published the first book on canning entitled “The Art of Preserving Animals and Vegetable Substances for Many Years”, the first known work on canning.

- Appert’s works involve packing the food in glass bottles, sealing it with a cork, and heating the container in boiling water for several minutes depending on the type of food.

- In 1810, Peter Durand received the first British patent on the canning of foods in tin or metal containers.

- In 1813, Dawkin, Hall & Gamble introduced the practice of post-processing of packaged foods.

- In 1825, T Kensett and E Duggett were granted US patents for preserving food in cans.

- In 1825, Thomas Kenett, an American, developed the first kettle pan.

- In 1839 tin cans came into widespread use in a limited number of states.

- In 1845 S Elliot introduced canning to Australia.

- Louis Pasteur (1864) discovered that food spoilage is caused by micro-organisms that are destroyed at high temperatures and the technique is known as pasteurization. This understanding helped establish a scientific basis for the canning industry and revolution.

- In 1873 Andrew Shriver developed the first retort pressure cooker.

- In 1890 Max Ann developed the first double seaming machine.

- 1895 Russell conducted the first bacteriological study of canning.

- In 1916 Bitting gave an index of the processing time and temperature relationship of food products.

- 1920 Ball, a mathematician, developed mathematical calculations for heat sterilization.

- 1921 The horticulturists, Magoon and Culpepper, proposed the idea of exhaust and vacuuming in processed products.

- The Civil War in America, and later the Boer War and the Great European War of 1914, further impetus the canning industry with a huge need for food for the fighting forces.

Containers for packaging canned products:

Mainly two types of containers are used in canning:-

1. Tin Container (Cans):

Metal cans are mainly used in national and international trade for canning fruits and vegetables. Open Top Sanitary (OTS) cans are made from tin plates which are very thin sheets of steel that are lightly coated with tin (0.00025 cm thick) on both sides.

Steel plate is difficult to coat evenly and small microscopic spots are always left uncoated during the manufacturing process, although the coating may look perfect to the eye. The contents of the can may react with these uncoated spots resulting in product discoloration or corrosion of the tin plate. When the corrosion is severe, iron sulfide forms dark spots. Therefore, it is necessary to coat the inside of the can with some material (lacquer) that prevents discoloration and does not affect the nutritive taste of the contents. This process is known as “lacquering”.

Two types of lacquers are used

1. Acid Resistant:- Acid Resistant Lacquer is a golden-colored enamel and can be coated with that is called R-enamel or AR cans. These cans are used to pack acidic fruits which are of two types

(a) which contain water-insoluble colours, such as peach, pineapple, apricot, grapefruit and

(b) those containing water-soluble colours, for example, raspberry, strawberry, plum, and colored grapes,

2. Sulfur resistant:- This lacquer is also golden in color and cans coated with it are called C-enamel or S.R cans. These are for non-acidic food only and should not be used for high acid products as the acid dissipates the lacquer. These cans are used for peas, corn, lima bean, red beans, etc.

Tin containers are preferred over glass containers due to certain advantages

a) ease of manufacture

b) strength to withstand processing

c) are lighter

d) ease of handling

e) cheaper and

f) Can be handled with high-speed machines.

2. Glass Container

Glass containers have distinct advantages over tin cans

a) visible content can be easily displayed, and

b) They can be used over and over again.

c) High-quality glass does not contaminate the food material,

Hence, such containers are preferred for packing baby food, but being fragile, require extra care during handling and processing.

Disadvantages of glass containers

- Glass containers are fragile/brittle, so great care is required when handling.

- Glass containers are heavy in weight.

- Disposing of glass containers is not easy.

Types of glass containers

- Bottles: The bottles have a narrow neck and a small closure at the top. The narrow neck facilitates insertion and minimizes the size of the closure. Bottles are used to pack liquids and small-sized solids.

- Jars: These do not have an appreciable neck but are wide-mouthed bottles. These are easy to clean and the product is easy to remove. These are used for packing jams and powders.

- Tumblers: These are similar to jars but have no neck and no finish. They can be used for packing jams and jellies.

- Jugs: These are large-sized bottles with handles to hold. Used to pack liquids, and foods in large quantities such as gallons or more.

- Vials: These are small glass containers. Vials are used for packing medicines whereas ampoules are used for packing small quantities like spices, food colours, fragrances, etc.

Steps of canning fruits and vegetables

1. Selection/Procurement of Raw Materials: For canning, fruits should be uniformly ripe, firm, and free from defects, insect damage, and deformities. Thus, harvesting at proper maturity is an important step in the selection of raw materials for canning.

- Apples, pears, peaches, and bananas harvested at the ripe stage are preferred for canning.

- Overripe fruits yield a poor-quality product, while under-ripe/immature fruits generally shrink or become hard during canning.

- Vegetables except for peas, beans, etc. are harvested at the mature stage so that they can tolerate heat during sterilization.

- Vegetables like green beans, green peas, and okra should be soft and free from soil, dirt, etc.

- Tomatoes should be hard, fully ripe, and evenly dark red in colour.

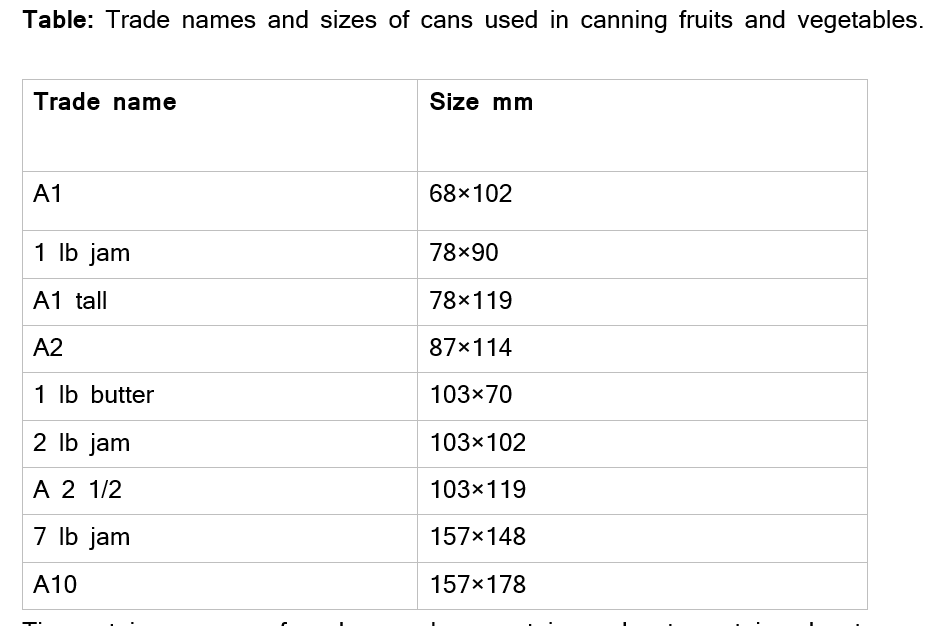

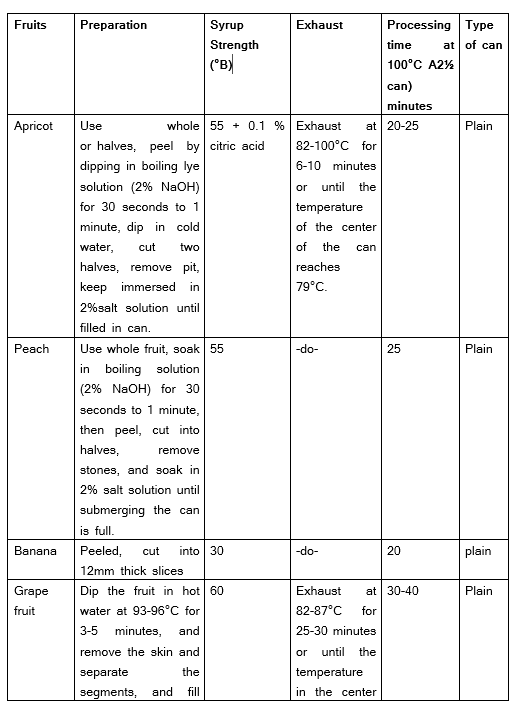

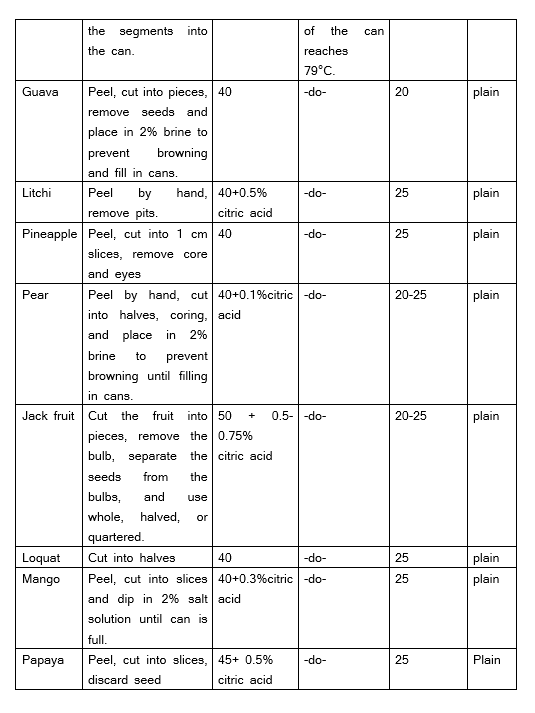

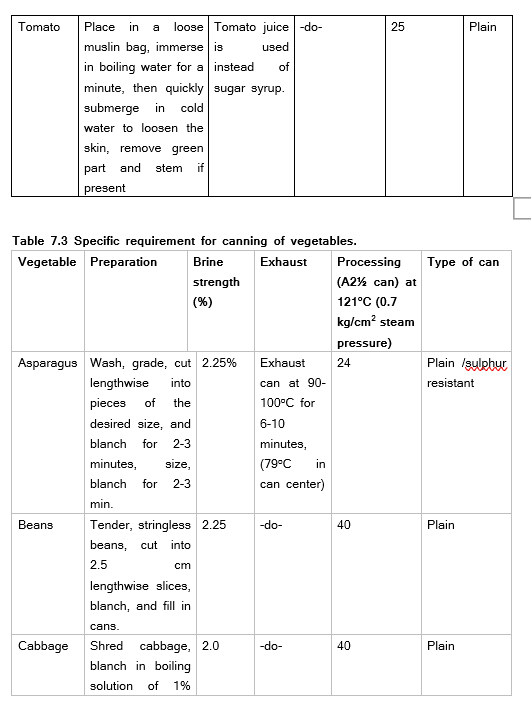

Table: Specific requirements for canning fruits

2. Washing: Fruits and vegetables are generally washed with water to remove dust, dirt, and surface micro-flora. Fruits like peaches, apricots, etc. are peeled off so they are not washed before peeling. On the other hand, washing after peeling removes vitamins and minerals so it should not be done. Various methods of washing include soaking or agitating in water, washing with cold or hot water spray, etc.

- Detergents are often used for washing in water.

- Vegetables can be soaked in a dilute solution of potassium permanganate or chlorine (25-50 ppm) for disinfection.

3. Sorting and Grading: Sorting and grading ensures the removal of inferior or damaged items. Inspection belts can also be used for sorting, along with trained personnel, who remove inferior quality products unsuitable for canning.

- Fruits and vegetables are graded after initial sorting to obtain a uniform quality with respect to size, colour, etc.

- An automatic color sorting machine can be used to reduce labour costs.

- For mechanical grading, fruits and vegetables are passed over a screen with holes of different diameters.

- Soft and berry fruits are generally graded by hand or manually.

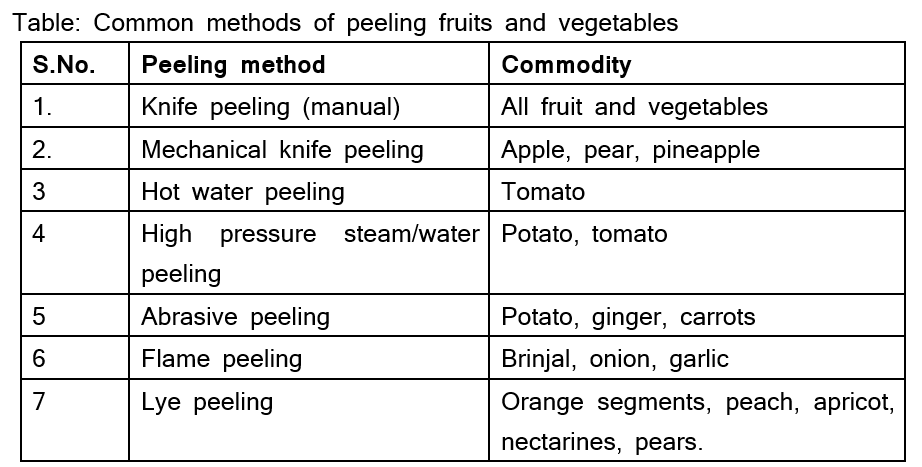

4. Peeling, Coring, and Pitting: These are the primary operations for preparing fruits and vegetables for canning. Depending on the type of fruit or vegetable, peeling and coring methods are selected such as (1) by hand or knife (2) by machine (3) by heat treatment (4) by using lay solution. In fruits like apples, peaches, apricots, etc., the core and pits are removed by hand or by machine (de-corer).

a) Peeling by hand: Many fruits and vegetables are peeled and cut by hand with the help of a knife. A peeling knife with a curved blade and a special guard to control the depth of peeling can be used for the uniform peeling of irregularly shaped fruits.

b) Mechanical Peeling: Mechanical peeling, coring, and cubing machines are used to peel pears, apples, carrots, turnips, potatoes, etc. Similarly, automatic peelers are used to peel peaches and cherries.

c) Mechanical /Knife peeling: Mechanical knife peelers are used for peeling fruits like apples and pears. In a mechanical knife peeler either stationary blades are pressed against the surface of the rotating food commodity or the rotating blades are pressed against the stationary food to remove the skin.

d) Abrasive Peeling: It is used for peeling potatoes, ginger, carrots, etc. The food item is poured into carborundum rollers or placed in a rotating bowl that acts as an abrasive surface with carborundum crystals. With a constant supply of water, the rotating abrasive surface removes the skin from the surface of fruits and vegetables.

e) Flame peeling: Flame peeling is used in onion, garlic, and brinjal. The peeler consists of a conveyor belt that moves and rotates the food through a furnace heated to over 1000°C. The outer layer and root hairs of the onion are burned and the burnt skin is removed by hand.

f) Peeling with heat or hot water: In this method peaches and potatoes are boiled or boiled in water to soften and loosen the skin, which is then removed manually. Infra-red heat peeling can also be used to peel apples and tomatoes.

g) Flash Steam Peeling: In flash-steam peeling, fruits and vegetables are put in a slow-rotating (4-6 rpm) pressurized vessel. High-pressure steam (1500 kPa) is used in a rotating vessel to steam all surfaces of the food for a specified period of time depending on the type of fruit. Immediately after the steam is released, the steam that builds up under the skin loosens the surface of the food. Most of the peeled material is removed with steam and finishing with a spray of excess water to remove any traces of skin.

h) Lye Peeling: Lye is a boiling aqueous solution of caustic soda (sodium hydroxide) or potassium hydroxide (1-2%) used for peeling with sufficient water supply and in combination with a heat source. Fruits and vegetables such as peaches, nectarines, apricots, orange segments, carrots, and sweet potatoes are peeled by immersing them in boiling caustic soda (1-2%) for 1–2 minutes followed by cold water. The warm lye loosens the skin from the pulp underneath which is removed from the fruit with a gentle hand rub. The fruit can be immersed in a dilute solution of hydrochloric acid or citric acid for a few seconds to neutralize the alkali. The method is very fast and efficient to reduce wastage and peeling costs. The effectiveness of lye peeling depends on lye concentration and temperature, product holding time, and agitation.

5. Cutting/halving/ slicing: After peeling, the fruits are halved or cored either manually or mechanically. However, peeled fruit should always be kept submerged in either water, containing 1-2 % salt solution or acid to avoid enzymatic browning. Peaches, apricot, pears, tomatoes, etc are peeled before canning. However, the fruits which are canned retain better nutrients as compared to peeled fruits.

6. Blanching: Treatment of fruit and vegetables with boiling water or steam for short periods followed by immediate cooling prior to canning is called blanching. The basic objectives of blanching are as follows:

- To deactivate enzymes

- To reduce the microbial load clean the product initially and heat the product before processing

- Cans to soften tissue to facilitate compact packing

- To remove the intracellular gases in the unripe fruit to prevent excessive pressure build-up in the container.

- For better heat transfer during heat processing

- To ensure vacuum in the can and reduce internal can corrosion.

Blanching is done either with hot water or by using steam. Water blanching is generally of immersion type or spray type as the product moves on a conveyor. Only soft water should be used for blanching as hard water hardens the tissues and destroys the natural texture.

7. Prevention of browning: Some fruits cannot be blanched due to their delicate tissue structure, treated with certain chemicals to prevent oxidative browning caused by exposure to oxygen during peeling and slicing. Oxidative browning is caused by the action of catechol and oxidase enzymes with tannins and is seen in peaches, apples, potatoes, mushrooms, cherries, apricots, grapes, and persimmons. Common methods used to prevent browning are as follows:

- Sulphite treatment: The fruits are immersed in a solution containing 2000-4000 ppm SO2 for 2-5 minutes. SO2 fumigation can also be commonly used when dehydrating grapes.

- Acids: Common acids used to increase acidity include citric, fumaric, tartaric, acetic, phosphoric, etc. The low pH of the solution is known to act as an inhibitor for the enzyme polyphenol oxidase, thus preventing the browning of fruits. Peeled fruits, slices, or cut surfaces are immersed in a solution of 1-2% citric acid to prevent browning.

- Antioxidant: Ascorbic acid is commonly used as an antioxidant in most canned fruits. It acts as an inhibitor of peroxidase in some fruits like kiwi fruit. It also reduces quinones, which are produced upon oxidation of polyphenols by polyphenol oxidase, into phenolic compounds and thus inhibits their conversion to brown pigments.

- Sugar: Sugar syrup is used to prevent browning in peeled and cut fruits by inhibiting oxidation by partially expelling air in the tissues. Sugar is combined with ascorbic acid and citric acid as an effective agent against loss of texture, color, and taste.

- Salt: Immersion of peeled and cut fruits and vegetables in 1-2% salt solution also does not cause enzymatic browning, as salt acts as an inhibitor of polyphenol oxidase.

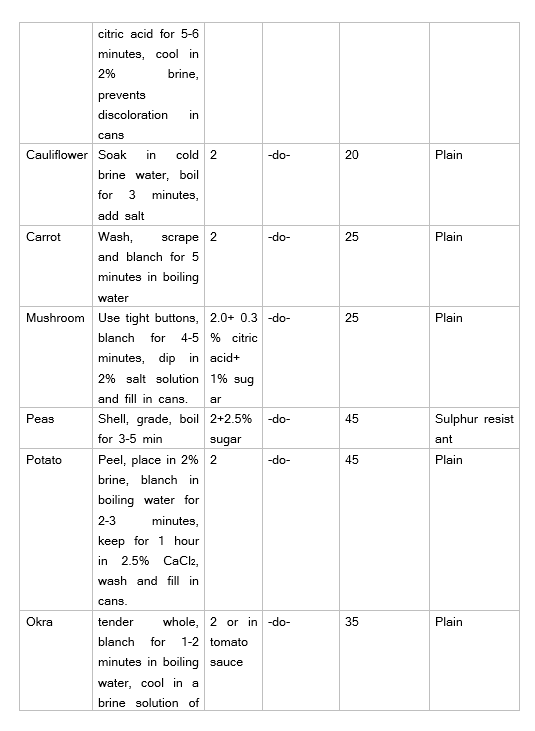

8. Filling in cans: Tin cans are washed in hot water or steam jets to remove any clinging dust or other substances. The can is then sterilized by immersing it in a hot water tank or the can is passed through a steam sterilizing tunnel before use. Generally, plain cans are used, however, for colorful fruits such as plums, black grapes, strawberries, etc; lacquered cans are used. Fruits and vegetables are packed in either slices, halves, or wholes, keeping in mind the weight.

9. Syruping or brining: Cans are filled with hot sugar syrup (35-55%) for fruits and hot brine (2-10%) concentrates for vegetables. The purpose of syruping or brining is to help with the transfer of heat within the food pieces during processing. It also improves the taste of the canned product, filling the gap between the fruits or vegetables in the can. The syrup or brine is filled into the can at a temperature of 79-82°C, leaving 0.32-0.47cm of head space.

10. Exhausting: Exhausting is a unit operation in which practically all the air is removed from the contents of the can before sealing. The purpose of creating exhaust and vacuum is to create an anaerobic environment in the can that will prevent spoilage by micro-organisms. Removing air from the material also reduces the risk of corrosion of the tin plate and pin holing and discoloration of the can material. The exhaust helps in better retention of Vitamin C. The expansion and shrinking of the contents during heating help to avoid over-filling of the can. (Corn and peas expand when boiled in salted water, while strawberries shrink when heated in sugar syrup). The vacuum in the can prevents the can from bulging during storage at high temperatures or in a hot environment. It also prevents excessive pressure and tension during sterilization.

There are usually three methods to exhaust the can to remove the headspace gas and create a vacuum.

- Heat/Thermal Exhausting: In this method the can cover with a lid or loosely sealed; the can is passed through a hot water tank of about 82-87oC or through a covered steam box on a moving belt. In the water exhaust box, the cans are placed in such a way that the water level remains 1.3-2.5 cm below their top. The exhaust time can range from 5 to 25 minutes depending on the nature of the product. At the end of the exhaust, the temperature in the center of the can should be around 79oC. During exhaust, steam replaces the air inside the can and is sealed only when heated.

- Steam flow or steam-vacuum closure: In this system, high-pressure steam (at 100°C for 5-8 minutes) is injected into the can headspace just before closing. Thus, all the air inside the can is quickly replaced by steam, which will condense and create a vacuum after sealing. Steam vacuum closure with hot fill creates a lot of vacuum in the can.

- Mechanical vacuum sealing: In high-speed mechanical vacuum sealing, cans filled with product and covering syrup or brine are passed inside a clincher that clinches the cans (the first operation is the roll seam) but does not have an airtight seal. The cans are subject to be vacuumed for a short time period to remove the headspace air. However, some syrup may also be released along with the dissolved air during this process. To avoid syrup spillage, a pre-vacuuming step is recommended prior to vacuum closing. High vacuum closing is also used for glass jars where the jars are kept in a closed chamber in which a high vacuum is maintained.

11. Seaming/Closing: Immediately after exhausting, the box is sealed using a double seamer.

It is necessary to close the container immediately to prevent excessive cooling of the surface of the product. Double seamers are of different designs and capacities such as hand-operated, semi-automatic, and fully automatic. Modern double seamers operate at high speed (300 cans per minute) while liquid products are sealed in the can at a speed of 1600 cans per minute.

12. Coding/Embossing: The coding on the lid of the can is required to identify it after it is closed. The code provides essential information about the product such as the name of the canning unit, the product packed in the can, the date of packing; lot number, etc. The coding is done on the second lid (end cover) of the can just before sealing.

13. Heat processing: After sealing, the contents of the cans are immediately transferred to heating retorts to be sterilized. In heat processing, containers are heated at a predetermined time and temperature to eliminate all possibilities of spoilage by microorganisms. Overheating should be avoided as it spoils the texture, taste, and appearance of the product. Generally, all fruits and acidic vegetables can be processed satisfactorily in boiling water (100oC) because the presence of acid inhibits the growth of bacteria and their spores. Whereas non-acidic vegetables (except tomatoes and rhubarb) are processed under pressure at a high temperature of about 115-121oC. This is done to ensure that the required temperature is reached at the center of the can. The temperature in the center of the can must be maintained long enough to destroy the spores of the more heat-resistant bacteria.

Processing methods vary according to the type of fruits and vegetables to be processed. Most fruits and vegetables with acid (pH < 4.5) cans are heated in open cookers, non-agitating cookers, and continuously agitating cookers.

14. Cooling: Immediately after processing, the sealed cans are rapidly cooled to about 35-40°C to stop the cooking process and to avoid burning the stock. Prolonged heating results in a poor and uneven product, such as peaches and pears darken, tomatoes brown and become bitter in taste while peas become mushy with over-ripe. Cooling is done by submerging or passing a hot can in cold water tanks, spraying the can with a jet of cold water, pouring cold water into a pressure cooker, or exposing cans to air. The water used for cooling must be non-corrosive, free of bacteria and yeast, and chlorinated.

15. Storage: After cooling, the cans are stacked to allow the outer surface to dry, as even a small amount of moisture is prone to rust. The cans are then labeled either manually or using a labeling machine and packed in a wooden or cardboard box. They should be stored in a cool and dry place (below 30°C). Adequately processed cans usually ensure acceptable product quality for at least one year. Storage of cans at high temperatures should be avoided to prevent thermophilic growth and the risk of spoilage.

Fruit and vegetable bottling

Bottles have proven to be very good containers for home preservation of fruits. Although their initial cost is high, they can be used multiple times and last for many years if handled carefully. The fruits look attractive through the glass and do not develop a metallic taste. Bottling does not require a sealing machine but is not suitable from the manufacturer’s point of view as the initial capital requirement is high. There are many types of glass containers of various sizes and forms and with different types of hermetic seals.

Process for bottling

- The bottles are thoroughly washed and disinfected.

- Fruit slices are filled leaving about 3 cm space at the top of the jar or bottle.

- The boiling hot sugar syrup recommended for various fruits is filled leaving 1-1.5 cm of head space.

- Exhausting and Sterilizing: Bottles do not require separate exhaust and are sterilized simultaneously by applying cloth pads (false bottom) to the bottom of the bottles.

- Bottles should not be suddenly immersed in hot water, otherwise, they may break due to a sudden rise in temperature. The temperature of the water should be the same as that of the contents and should be increased gradually and the bottles should be placed in boiling water for the required amount of time.

- At the beginning of sterilization, the lids are left loose and the boiling water level should reach the neck of the bottle.

- When the sterilization process is over, the mouths of bottles and jars should be tightly closed immediately.

- The bottles are cooled and the bottles are labeled after drying. Products preserved in bottles require more attractive labels.

- Store in a cool and dry place.

Reasons for spoilage of canned foods

The spoilage of canned products can happen for two reasons:

(A) Physical and chemical changes

(B) by microorganisms

(A) physical and chemical changes

1) Swell: – When the bottom (end) of a clearly normal and perfect can with a good vacuum bulged, it is called ‘swell’ or ‘blower’. The bulge is caused by the positive internal pressure of gases formed by microbial or chemical action.

- Hydrogen Swell: This type of bulging is due to hydrogen gas produced by the action of food acid on the metal of the can. Swell ranges from ‘flipping’ to ‘hard swell’. The food generally remains free of harmful microorganisms and is fit for consumption.

- Flipper: Can appear normal, but when placed on tabletop one or both ends protrude but can be pushed back to normal position with slight pressure. Such a can is called a ‘flipper’ and may be an early stage of swell or hydrogen swell. It can also be due to overfilling or low exhaust or gas pressure produced due to spoilage.

- Springer: A slight bulge at one or both ends of a can is called a ‘springer’ which may be the initial stage of hydrogen swell or may be due to overfilling or insufficient exhaust of the can. The protruding end (or at least one end) can be pressed back to the original position but will re-emerge after some time.

- Soft swell: In this stage, both the ends of the can protrude which can be returned to normal position by pressing, but return to the same position when the pressure is released. This type of swell is called a “soft swell” and is almost the same as a flipper.

- Hard Swell: This is the last stage of swell. The protruding ends cannot be pressed back to the normal position and the cans eventually burst.

The following precautions are necessary to prevent hydrogen swell:

i) Good quality tin plates should be used for making cans. The quality is related to the porosity of the tin coating. The higher the porosity, the greater the chance of corrosion.

ii) About 0.5% citric acid should be added to the syrup used for canning low acidity fruits like cherry, mango, papaya, etc.

iii) A head space of 0.6 to 0.9 cm should be left in the can putting the lid before the exhaust.

iv) The lid should be firmly closed or clinched before exhaust to ensure a high vacuum in the can.

v) The can should be exhausted for a sufficiently long time, but without undue influence on the quality of the product.

vi) The temperature at the time of sealing should not be less than 74°C.

vii) Hydrogen formation will be high at high storage temperature, which will eventually result in bulging of the can, so canned products should be stored in cool and dry conditions.

2) Overfilling: Damage due to overfilling is common. During heating, the contents of the overfilled cans become stressed due to expansion, and they swell due to the absence of vacuum. If the cans are properly exhausted, the excess material is released due to expansion and thus, spoilage due to overfilling is avoided.

3) Faulty retort operation: When the steam pressure is rapidly reduced at the end of processing, a high vacuum develops inside the cans resulting in deformation of the cans, and the cans appear ‘swell’ upon cooling. Very thin tin plate cans should not be used because they cannot withstand the pressure that develops in the cans during processing.

4) Under-exhausting: The cans are exhausted to remove most of the air. This helps to fill the fruits and vegetables properly and also creates a good vacuum, which is necessary to accommodate any pressure that may develop inside the cans as a result of hydrogen production due to corrosion.

The large internal pressure of the gas present in improperly exhausted cans can cause serious strain during heat processing. Low-exhaust cans show strain ranging from minor flipping to deformation, depending on the amount of gas released from the product and the size of the can. All the gas should be removed by tilting the can and pressing its ends. A longer exhaust at a lower temperature of about 79°C gives better results, while a shorter time of about 87°C is fine, provided the cans are closed at the same temperature. However, the advantage of exhaust, cans are quickly lost if they are allowed to cool significantly before closing. Therefore, any improper cooling of the cans after exhaust and before closing should be avoided.

5) Paneling: It is generally seen in large-sized cans that the body is pushed inwards due to the high vacuum inside the body. This also happens when the tin plate is thin or the can is cooled at very high pressure. In very severe cases, seam leakage may occur but is not usually considered spoilage.

6) Rust: External rusted can should be thoroughly examined and, if pits are visible in the walls, they should be considered defective and removed. Cans slightly affected by rust should be discarded if not used immediately. Rust is mostly seen under the label and later affects the label as well. Even if the cans are externally coated, rusting should be checked.

7) Foreign Taste: During preparation, filling, storage, or even transportation, anywhere conditions can become unhygienic and the product may develop foreign or “off flavours”. If inappropriate metal containers are used, a “metallic taste” may also develop. Tin packages should be checked at regular intervals, as taste is an important characteristic.

8) Damage: Due to carelessness or ignorance, bad handling of cans can result in damage to them. If any can show signs of leakage or serious deformation it should be rejected.

9) Undesirable texture: Texture is another important characteristic, such as taste and colour, which can be easily recognized by consumers. The texture of a product should be tested from time to time to maintain the standard. Although there are no precise parameters to measure texture, instruments such as a “tenderometer” that measure resistance to shear and relative tenderness can be used for peas and beans.

Calcium salts present in the water used for canning have a “hardening effect” on peas and beans, but such hardening is considered desirable for potatoes and tomatoes.

10) Corrosion of cans: The acidity of the contents, especially the highly acidic fruit, causes the cans to become corroded or punctured. In recent years, attempts have been made to reduce corrosion by using improved lacquers for the interior coating of cans.

11) Leakage: A leaking can is referred to as a “leaker”, it can be caused by: a) faulty seaming, b) faulty nailing of the nail hole while packing, c) spoiled by microorganisms Bursting due to excessive internal pressure d) internal or external corrosion, and e) mechanical damage during handling.

12) Breathing: There may be a very small leak in the can through which air can get in and destroy the vacuum. The food is damaged by rusting in the can due to the oxygen in the air but still remains fit to eat.

13) Bursting: This can be caused by excess pressure of gases produced by the decomposition of food by microorganisms, or by hydrogen gas formed by the chemical reaction of food acids on the tin plate. In such cases, the packaged product is not suitable for use.

14) Buckling: Sometimes due to improper cooling, takes place a ‘swell’ like a deformity. Although the deformation can be corrected by pressing, cans are often badly strained and the material gets spoiled due to the penetration of microorganisms through the seams. This type of spoilage is known as ‘buckling’. Sometimes a peak or small ridge form on the can which is known as ‘peaking’.

15) Discoloration: This can be detected by visual examination of the can and its contents. The discoloration may be due to biological causes such as enzymatic and non-enzymatic browning or metal contamination. Enzymatic browning caused by the enzyme polyphenol oxidase present in fruits and vegetables can be avoided by placing peeled and cut pieces in a 2% salt solution. Non-enzymatic browning is caused by the reaction between a) nitrogenous compounds and sugars, b) nitrogenous compounds and organic acids, c) sugar and organic acids and d) the organic acids themselves. These reactions are known as Maillard Reaction.

Metallic contamination is mainly caused by iron and copper salts. Some fruits and vegetables contain tannins that react with the metal of the tin plate to form black ferric tannate, which spoils the food. Sometimes hydrogen sulphide gas is produced from the reaction between the fruit acid and the tin coating, which reacts with the iron of the tin plate to form black iron sulphide. Copper also forms black copper sulphide when exposed to hydrogen sulphide. Metal contamination can be avoided by using glass containers, coating the interiors of cans with lacquer, and eliminating the use of iron and copper utensils.

16) Stack burning: If the processed can is not allowed to cool sufficiently before storing, the contents remain hot for a long time. This is known as ‘stack burning’ which results in discoloration, cooked taste, and a product that is very soft or pulpy. Therefore, cans must be quickly cooled to approximately 39 °C before storage.

B) Microbiological spoilage

1) Pre-processing spoilage: This type of spoilage occurs due to the time lag between the filling of containers and heat processing. However processing inhibits the growth of organisms, so delays between filling and processing should be avoided.

2) Under-processing spoilage: Packaged foods are spoiled by thermophilic bacteria and mesophilic organisms as a result of under-processing and are called ‘under-processed’ spoilage.

a) Thermophilic bacteria: These bacteria can thrive at a high temperature of 100 °C. If the can is stored without sufficient cooling, the contents remain at a temperature conducive to the incubation of such bacteria for a long time, resulting in the growth of these bacteria and spoilage of the product. Therefore, it is necessary that the cans be cooled to approximately 39 °C before being stored. Thermophilic bacteria grow by forming spores, some species, called facultative, grow at 43 °C while others, called obligate, grow at 43 °C to 77 °C. The obligate is more difficult to kill than the facultative. Some generate thermophilic hydrogen, and others produce hydrogen sulphide gas that darkens containers. The only way to avoid bacterial contamination is to thoroughly clean and wash raw materials before canning. The sources of bacterial contamination are plants, equipment, sugar, starch, soil etc.

i) Flat sour: This occurs mostly in non-acidic foods such as vegetables and is caused by thermophilic bacterial species Bacillus coagulans and Bacillus sterothermophilus, which produce acid without gas. Therefore, it is difficult to detect the spoilage from the external appearance of the can. This is almost entirely caused by under-processing. The product has a sour smell and its acidity is much higher than that of the ordinary product. It is not fit to eat.

ii) Thermophilic acid (TA) spoilage: In the case of TA spoilage, the can swell due to the production of carbon dioxide and hydrogen by Clostridium thermosaccharolyticum. Such spoilage occurs in most foods with low and medium acid. C. thermosaccharolyticum is an obligate thermophile and, therefore, grows in cans stored in warm conditions.

iii) Sulphide spoilage (Sulphur stinker): This is caused by Clostridium nigrificans in low acid foods. The spores of this bacterium are not very heat resistant and their presence is a sign of less processing.

b) Mesophilic organisms: Deterioration by mesophilic organisms such as Clostridium, Bacillus, yeast, and some species of fungi is also a sign of under-processing.

Clostridium butyricum and C. pasteurianum cause butyric acid-type fermentation of foods, with container bloating due to a build-up of carbon dioxide and hydrogen. Other species of Clostridium produce hydrogen sulphide and other undesirable gases. These putrefactive anaerobes usually thrive in low acid content such as vegetables, etc., but sometimes in moderately acidic food as well.

Some gas-forming bacilli such as Bacillus polymyxa and B. macaron also cause spoilage of canned peas, spinach, peaches, and tomatoes.

3) After processing

Infection due to leakage through seam: A large number of cans after processing show signs of spoilage by microorganisms due to leakage of the can seam. Water-cooled cans are more likely to leak than air-cooled cans. Thus, the cans may or may not swell depending on the type of micro-organism and if there is a defect in the seam it allows free passage of the gas that builds up in the can. In addition, buckling also allows the entry of microorganisms.