Preserve

A fruit Preserve is made by cooking the fruit whole or as large pieces in heavy sugar syrup until it becomes tender and transparent. As per FPO specification, the preserve contains 68% TSS and 55% ready fruit (w/w).

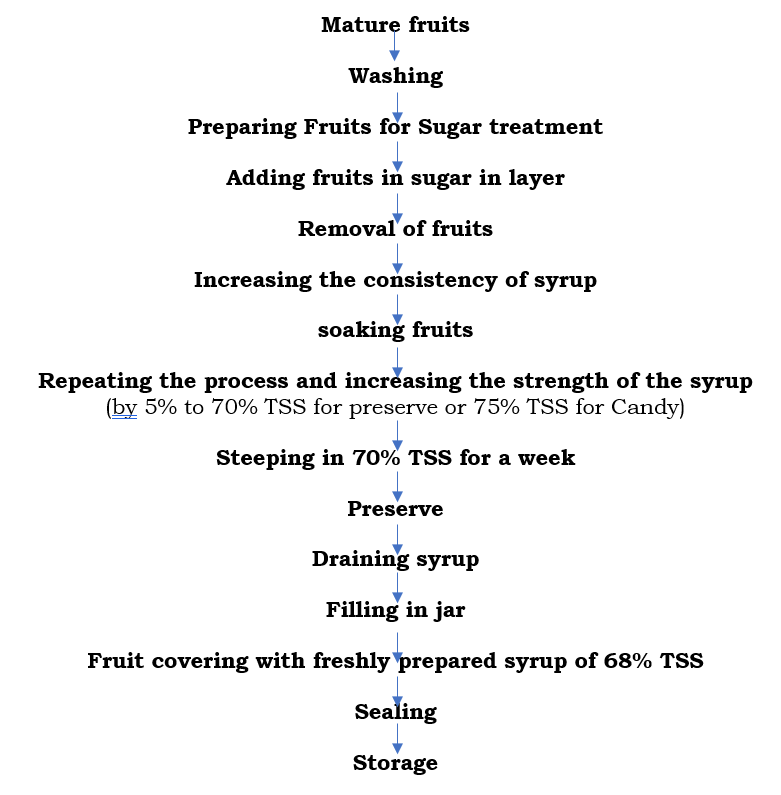

Process of preparation of preserve:

In the preparation of preserve, at least 45 kg of fruit is used for every 55 kg of sugar and cooked until a concentration of at least 68 percent soluble solids is reached.

Watch Lecture Video

Flow sheet for Preserve and Candy

Fruit Selection: Fruits should be fully developed, firm, and slightly under-ripe. Raw or overripe fruits with loose flesh should be rejected.

Fruit preparation: The fruit is washed thoroughly and the damaged part is removed. Fruits with thin skins, such as berries, do not require peeling. Fruits with thick peels such as mango, apple, bael, and pumpkin are peeled. The core, seeds, or kernels are removed. The fruits are prepared either whole or in pieces.

Pricking/puncturing: Whole fruit or slices are uniformly punched with stainless steel/wooden prickers to enable proper penetration of sugar syrup. Excessive pricking should be avoided to avoid softening of fruits/pieces. Amla and Pumpkin can be pierced using mechanical pickers.

Soaking: The fruits or their slices are soaked in water, brine, or alum solution for a few hours to a few days before blanching which enables the syrup to penetrate properly. Soaking makes hard fruits porous, avoids browning, removes astringency, reduces shrinkage, and fruits do not harden.

Blanching: The soaked fruits or slices after washing thoroughly are placed in a muslin cloth and blanched in boiling water for a few minutes (5-10) according to their texture to soften the tough texture. However, excessive blanching should be avoided.

Preparing the syrup: The amount of sugar varies for different fruits, ranging from as much as twice the amount of prepared fruit or pieces. The syrup is prepared by boiling sugar in water and adding 0.3-0.4% citric or tartaric acid. The acid also helps remove dirt from the sugar.

Cooking in syrup: The prepared fruits or pieces are cooked in syrup in three different ways which are as follows-

- Open kettle one-time process

- Open kettle slow process; And

- Vacuum cooking process

1. Open Kettle One-time process: The fruits are cooked in low-sugar syrup. The syrup is heated lightly and continued to boil until the syrup is sufficiently thick. The final concentration of sugar should not be less than 68°Brix corresponding to the boiling point of 106°C. Boiling too quickly and on high heat should be avoided, as it makes the fruits tough.

2. Open Kettle Slow Process: In this process, sugar equal to half the weight of the fruit in the prepared fruit or pieces is poured into a pot in alternating layers and allowed to stand for 24 hours. During this period, excess water is removed from the fruit and the sugar turns into a solution of 37-38° Brix. The concentration of the syrup is increased to 60° Brix by adding more sugar. Citric or tartaric acid @ 0.06-0.12% is added to invert the sugar portion. The whole mass is boiled for 3-4 minutes and kept overnight. On the third day, the concentration of the syrup is raised to 68° Brix by adding more sugar and the whole mass is boiled again for 3-4 minutes and the fruit is then left in the syrup for another 3-4 days. Finally, the strength of the syrup is increased to 70° Brix and packaged in protected containers. However, the stages may vary with the type of fruit.

3. Vacuum cooking process: Vacuum cooking helps in retaining the better taste and color of the product. In this process, the fruit is initially softened by boiling and then placed in a syrup of 30-35° Brix concentration. The fruit syrup mixture is then transferred to a vacuum pan and concentrated to 70° Brix under low pressure. Hard fruits are slow-cooked to facilitate the penetration of sugar.

Precautions during cooking: In these methods, a deep pan should be used otherwise syrup may concentrate in a shallow pan within a short time and fail to penetrate the fruit. While adding the fruit pieces to the boiling syrup, the consistency should not be too thick. The thick syrup is unable to penetrate into the pieces and causes the product to harden or shrink. The fruits should always be kept covered in sugar syrup to avoid drying the top pieces and to improve the quality.

Cooling and packing: For bulk storage, the preserve is quickly cooled after the final boil to avoid discoloration. To pack in A2½ sized cans, the preserve fruits are dried and stuffed into the cans. The freshly prepared boiling syrup (68° Brix) is then poured into containers (A2½ sized cans), then sealed, sterilized at 100° C for 20-25 minutes, and immediately cooled.

Candied Fruits

Prepared fruits immersed in cane sugar or glucose syrup, later drained from syrup and drying. The candy-making method is practically the same as that used for making preserves, with a slight variation that the higher concentration of fruit sugar or glucose is maintained. To prevent fermentation, the total sugar content of the steeped fruit is kept at around 75 percent. Fruits best suited for candy making are those that have pronounced flavors, such as orange, lemon, grapefruit, and ginger. Other fruits like Amla, Karonda, Pineapple, Cherry, Papaya, Apple, Peach, etc. are also suitable for candied fruits.

Procedure for preparing candied fruits

Preparation of fruits: The stored fruit or slices are taken out of the barrel/tin and washed thoroughly under running cold water to remove as much brine as possible. The fruit or slices are then placed in a soak and boiled for about 15 minutes to remove traces of salt and soften its texture.

Cooking in syrup: The prepared fruit or slices are boiled in sugar syrup (30°Brix) by adding 0.1% citric or tartaric acid, boiled for 10-15 minutes, and then left in the syrup for about 24 hours. The next day, the concentration of sugar syrup is increased to 40°Brix by adding more sugar. The whole mass is boiled for about 5 minutes and left for 24 hours. The process is repeated until the syrup reaches 60°Brix. The concentration of this syrup is increased progressively to 75°Brix at the rate of 5°Brix by boiling the mass every alternate day.

Draining and drying: After sugar syrup treatment, the fruits or slices are removed from the syrup and dried for about half an hour, and sorted to remove any defective and unwanted pieces. Thereafter, the fruits/slices are immersed in boiling water for a moment to remove the sticky syrup and then slowly dried in shade or in a drier at 66°C for 8 to 10 hours.

Glazed fruit

Covering candied fruits with a thin transparent coating of sugar that gives them a shiny/glaze appearance is known as glazed fruit. For the glazing process, the syrup is prepared by boiling sugar and water in a 2:1 ratio in a steam pan at 113–114 °C and cooling to 93 °C. The sugar syrup is then rubbed with a wooden spatula on the side of the pan to make sugar granular. Dried candied fruits are passed through this granular portion of sugar syrup and then placed on a tray for drying at 49°C for 2-3 hours. When the pieces become crunchy, they are packed in an air-tight container.

Crystallized Fruits

Candy fruits are called crystallized fruits when they are covered or coated with fine sugar or coarse sugar crystals. The candied fruits are placed on a wire mesh tray which is placed over a deep vessel. Cooled syrup (70% TSS) is gently poured over the fruit so that it is completely covered. The whole mass is left undisturbed for 12-18 hours, then it is poured into a tray of fine or coarse granulated sugar and stirred to form a thin layer of crystallized sugar. The fruits are then placed in a single layer on a wire mesh tray and dried at room temperature or in a dryer at about 49 °C.

Packaging:

For retail trade, tin containers (15-20 kg capacity) and glass jars are used for storing preserve. Candied and crystallized fruits are packed in waterproof paper or polythene. Attractive porcelain jars are sometimes used to pack these products for the specialized export market. In addition to metal and glass containers, new flexible films can also be used, which are inexpensive and highly effective.

Defects and spoilage

Deterioration due to fermentation occurs in the early stages of preserve and candy preparation when the sugar content of the syrup is low. This can be checked by properly boiling the product at appropriate intervals. Keeping candy/glazed fruits in wet containers or in damp conditions causes spoilage due to mold growth. Thus, storing such products in airtight dry containers is recommended. Some defects are given below.

- Shrunken preserve: Due to the high concentration of syrup, the fruit/pieces of preserve shrink, so sugar and water should be mixed in a proper proportion, or sugar syrup should not be used at more than 70° Brix in the preserve.

- Dull brownish colour or cloudy appearance: Sometimes preserve becomes dull brown and cloudy due to the low quality of the fruit. Overcooking after the addition of sugar also makes the preserve cloudy. That is why fruits of good quality should be selected and the fruits should be cooked for a specified period after adding sugar.

- Tough fruit skin or peel: Sometimes the fruit or peel is not cooked until it becomes soft before adding sugar and it becomes hard when it is put in sugar syrup. Cook the fruit or peel until soft and then add sugar.

- Moulds on the surface: Sometimes, due to the inferior quality of the fruit, due to Undercooking, or when stored in a warm and damp place, a layer of mould appears on the surface of the preserve. That is why good quality fruits should be selected, fruits should be cooked for the proper time and stored in a cool place.

- Fermented preserve after storage: If less amount of sugar is used in preserve, fermentation starts during storage. Fermentation can also be caused by undercooking or by storing it in a warm place. An appropriate amount of sugar should be used to preserve. And it should be cooked until the endpoint and it should be stored in a cool place.

- Sticky candy (after drying): Sometimes candied fruits become sticky after drying because the final syrup is not concentrated enough. Always make a syrup of the right concentration.

- Sticky during storage: If candied fruits are not properly packaged or stored in a dumping place, they become sticky during storage, should always be stored in a dry and cool place and a proper concentration of sugar syrup should be used.